Development

Roadmap to Full Scale Production

We are developing in-situ robotic quarrying systems that convert natural stone directly into construction-grade bricks at the quarry face. Targeting the $1T+ bricks and dimension stone markets.

Timeline

Our Development Roadmap

From digital twin to full-scale production deployment.

Software Development

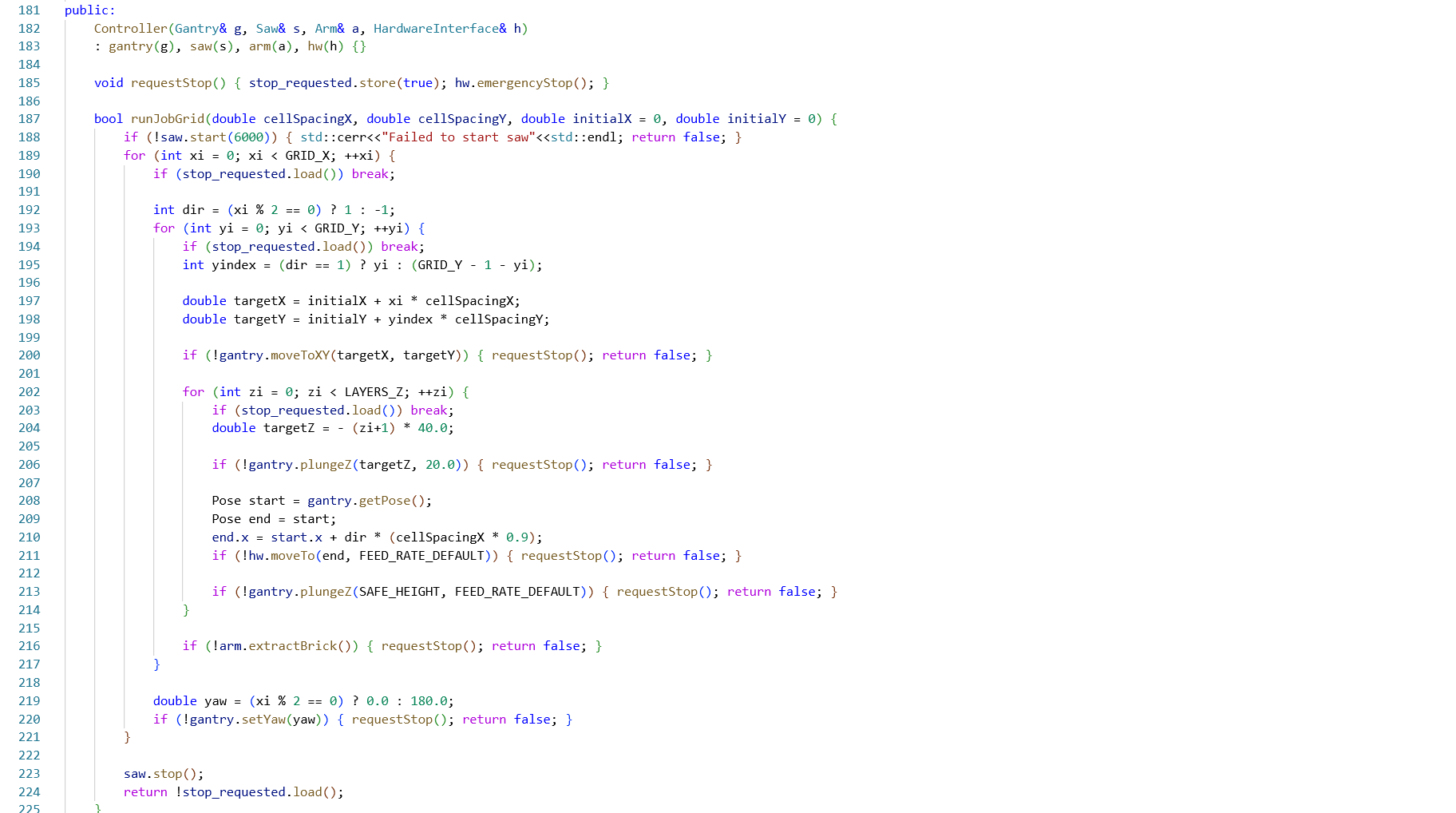

Complete the digital twin and simulation environment modelling the full in-situ stone cutting process, including laser-based positioning, self-levelling, sawing paths, extraction sequences and structural loading.

Physical Production

Begin production of the physical system and commence operational tests. Hardware manufacturing using easily purchasable parts.

Scale & Deploy

Scale operations and deploy systems to quarry sites. Become the first vertically integrated company to provide housing materials directly from quarry.

Strategy

Research & Development Goals

Five-year technical and commercial roadmap covering system industrialisation, market entry, investment strategy and national-scale deployment

Defined business plan and investor pitch framework aligned with phased manufacturing scale-up, unit economics and public-sector procurement pathways

Scalable industrial operating model designed for minimal human intervention, remote supervision and predictable operational costs

Software and control-layer maturation plan focused on reliability hardening, automated compliance verification and fleet-level optimisation

Detailed R&D documentation is available to investors upon request.

Request AccessInterested in Our Progress?

Explore our research papers or get in touch to learn more about investment opportunities.